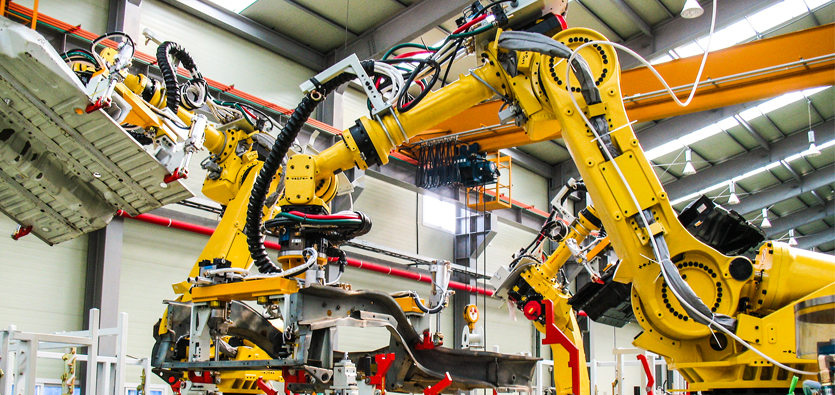

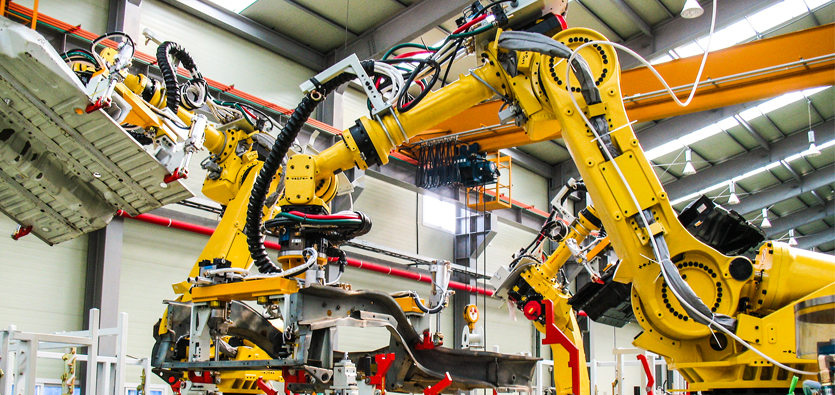

Robotic welding refers to the use of programmable devices to perform welding operations in high production applications. It was the automotive industry which employs robots for spot welding purposes for the very first time in the 1980s. A total of 31,464 industrial robots valued at $1.8 billion were ordered from North American companies during 2015.

In the modern manufacturing and fabrication processes, results are measured in terms of consistency, productivity, and adaptability. Companies have to continuously improve production output and minimize errors while maintaining the costs to an acceptable level. Robotic welding systems can help businesses, both small and large, achieve these goals. However, serious planning is required in order to make a maximum use of automated industrial machines.

The initial cost of automating a production process is generally high and manufacturers have to train the employees so that they can understand the functionality of a brand new technology. However, taking into account the long-term benefits of automation, robotic welding cells provide a cost-effective solution to achieve enhanced repeatability, accuracy, and throughput. Following are some of the factors that will help you understand how to make a good use of your robotic welding units.

Parts design and additional equipment

It is of great importance to have repeatable and accurate part designs in order to bring about the desired results. Poor joint access or gaps can make it really hard for an automated welding device to produce the quality weld. Moreover, integration of certain additional equipment can enhance the performance of a robotic welding system. These additional equipment include spatter cleaner, neck alignment, and wire cutter.

Return on investment

Automation technology has the potential to payback quickly. When it comes to the welding technology, payback is measured in form of superior quality welds and a dramatic increase in productivity. Some of the other paybacks include decreased labor, efficient use of materials, and low energy costs. One of the disadvantages of using a manual machine is overwelding that can be avoided with robotic welds. Therefore, companies should not be worried about the upfront cost of getting automated welding solutions.

Properly trained operators

Trained professionals are absolutely important when it comes to the maintenance and supervision of welding robots. Which means companies should make sure that they have skilled and experienced operators before bringing in the automated devices. A well-trained and experienced operator can troubleshoot and operate the device with ease. In addition, preventive maintenance can help reduce the downtime and keep the robotic welding system is good shape. Conclusively speaking, considerate planning, equipment selection, and skilled labor can help you make the most out of your investment.

About us

BP Automation has been providing economically viable and profitable automation solutions to the manufacturing industry in Canada for many years. We build custom machines to fix your unique and complex manufacturing problems. We also provide technical assistance and retrofit expertise. Reach us now to know more about our products and services.